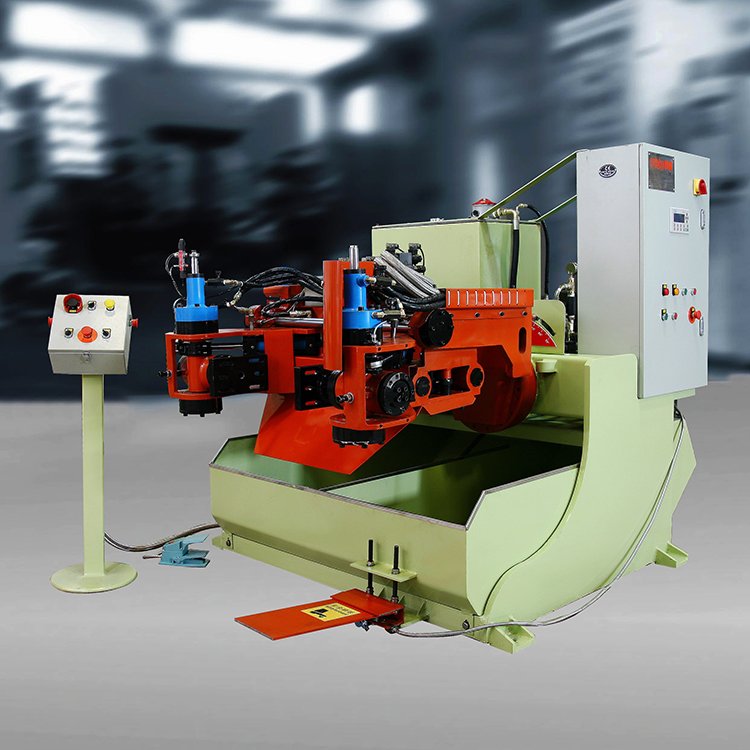

PN2B03B-135 The Gravity casting machine is suitable for gravity casting of brass, copper and ferrous alloys, and is characterized by a side casting angle of 0-135°, a front casting angle of 0-110° and a dipping angle of 0-90°. And the mixing method of the dipping tank is carried out by means of a vane type electric machine.

Technical Parameters:

- Controlled by a PLC control unit.

- Running: Hydraulic Transmission.

- The stir method of dipping tank: By vane electric machinery.

- Casting Function: Side pouring, frontal pouring, Combined pouring

- Casting speed & angle are adjustable. Side angle: 0-135 degrees, frontal angle 0-110 degrees, mold steeping angle 0-90 degrees.

- Max. Mold diameter: 500mm

- Max casting volume:150kg

- The time & frequency of cooling can be set up individually.

- Casting method: Automatic & Manual.

- Ejection function (optional)

- Having Safety foot board

- One cycle total time: 20-30 seconds.

- Pump power: 3.75KW+0.75KW+0.75KW

- dimensions (L*W*H) (1500*2400*1800)MM

- Have CE certification

Advantages of the PN2B03B-135 copper gravity die casting machine

- 1) Configuration: Equipped with PLC from Siemens, part of the important electrical and hydraulic components are imported from abroad, the quality of the equipment is stable.

- 2) Function. Front pouring can reach 115 degrees, side pouring can reach 135 degrees, secondary pouring and mixed pouring can be selected. The way and speed of pouring can be adjusted and controlled.

- 3) Market and quality: PINO brand originated from Taiwan and entered China in 1988, which is the first batch of gravity casting machine brands in China.

- 4) Certification: All gravity casting machines are CE certified.

Applications

Widely used in brass and copper alloy castings for water meters, faucets, valves, auto parts, etc. You can show your casting drawing or sample to our engineer, we will recommend the right machine for you, our senior engineer has 30 years experience in gravity casting and will recommend the most suitable machine for you.

Why is copper suitable for gravity casting

Copper has very good casting performance and casting quality in the gravity casting process due to its high thermal conductivity and good liquid fluidity. In the gravity casting process, the copper liquid flows into the mold naturally by gravity, without high-pressure or high-speed injection, which can avoid the damage of the mold due to high-pressure injection, and can also reduce the pores and inclusions inside the casting, and improve the quality and quality of the casting. reliability. In addition, copper has a low thermal shrinkage rate and good processing performance, and can be easily processed and handled later, so it is widely used in the manufacture of various mechanical parts, electrical devices, pipes and devices in gravity casting.

Our service.

We have perfect company service system as well as factory management system, complete quality assurance system

- We can recommend the right gravity casting machine according to the casting you want to produce.

- After-sales service system

- Our sales manager will keep in touch with you and respond to your questions in time

- Our technicians can be dispatched to your factory and they will help you with installation, maintenance and training.

- We provide detailed manuals of the equipment and set the operating system language of the equipment to your language of use.