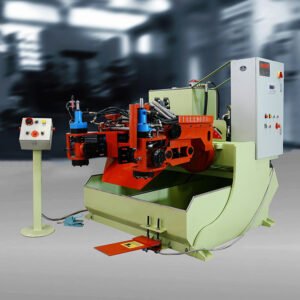

PN1A02S-B automatic sand core making machine is an efficient and precise equipment, which can bring convenience and reliability to the user’s sand core production process. The following is a detailed introduction of the device.

sand core making machine Technical Parameters:

PLC control unit control

The PN1A02S-B fully automatic sand core machine is controlled by a PLC control unit, which means it can perform efficient and precise operation and control, bringing users a better experience in use.

Pneumatic transmission operation

PN1A02S-B automatic sand core machine adopts air pressure transmission operation, which can make the sand core production process more stable, and can also bring higher production efficiency to users.

Various modes of operation

PN1A02S-B automatic sand core machine has multiple operation modes, including manual, semi-automatic and fully automatic with conveyor belt, etc. Users can choose the most suitable operation mode according to their own production needs.

optional power

The power of PN1A02S-B automatic sand core machine is optional, there are 12 heating tubes on each side, and each power is 1000W, which makes the equipment faster and more efficient when heating the core box.

Multi-cavity core mold

PN1A02S-B automatic sand core machine can choose dry core or wet core in the multi-cavity core mold, which can meet the production needs of different types of sand cores.

Automatic thermostat control

PN1A02S-B automatic sand core machine adopts electric heating element heating, automatic constant temperature, dynamic and static mold can be controlled separately, can accurately control the temperature of the core box, and ensure the stability of the production process.

Mandrel automatic cleaning

PN1A02S-B automatic sand core machine has automatic core mold cleaning function, which can make the equipment more intelligent and convenient.

Clamping stroke and ejection stroke

PN1A02S-B automatic sand core machine has a clamping stroke of 300mm, which can meet the needs of different core box molds, and also makes the equipment more suitable for various production environments. The ejection stroke is 30mm, the moving mold is mechanical, and the static mold is pulled by the oil tank, which can ensure the stability and reliability of the equipment.

Core Pulling Function

Standard stroke is 150mm, adjustable. The machine has an efficient core-pulling function, which can quickly and accurately pull out the core mold during the production process to ensure the quality and efficiency of the product.

The maximum focal length of the shooting material hole: 320mm

The shooting function of this machine is very flexible and can meet various production needs. The maximum focal length of the shooting material hole is 320mm, which can ensure that every detail of the product can be captured, thereby improving the accuracy and aesthetics of the product.

There are two security doors

Safety is a very important part of production, the machine is equipped with two safety doors to ensure the safety of operators during operation. Once an abnormal situation occurs, the safety door can quickly cut off the power supply to avoid accidents.

Fixed floodlights inside the machine

In order to facilitate the operator to observe the production process, the machine is equipped with a fixed floodlight inside to ensure that the production process can be clearly observed in a dark environment.

Air pressure operation tension: 0.5~0.7Mpa

The air pressure operation tension of the machine is between 0.5-0.7Mpa, which can ensure the smoothness and stability of the operation process, thereby improving the consistency and precision of the product.

Theoretical cycle time in minutes: 20 seconds

With a theoretical cycle time of 20 seconds, the machine has high-efficiency production capacity and can greatly improve production efficiency.

Maximum weight of mandrel: 4000g

The maximum weight of the core mold of this machine is 4000g, which can meet the production needs of various products.

Heating plate size 350×220×60mm

The size of the heating plate of the machine is 350×220×60mm, and the size of the heating plate can be adjusted according to the production demand, so as to ensure the balance between production efficiency and product quality.

Maximum mold size: 400×270×120mm per side, distance between two heating plates: 460mm.

The maximum mold size of this machine is 400×270×120mm per side, and the distance between two heating plates is 460mm, which can adapt to different types of mold requirements, thus ensuring the high efficiency and flexibility of the production process.

Machine size: 3160×650×2400mm.

The size of the machine is 3160×650×2400mm, does not take up much production space, and can be conveniently placed on the factory production line, thereby improving production efficiency and utilization.

Details of PN1A02S-B sand core making machine

The shape of the sand core can be determined according to the needs of the product, because the sand core is made to form the inner cavity in the casting. Common sand core shapes include: cylindrical, conical, square, rectangular, triangular, prismatic, etc. Depending on the internal structure of the casting, the shape of the sand core will vary. The shape and dimensions of the sand core need to be precisely controlled to ensure that it will snap into place during casting and properly separate out the internal cavity of the casting.

Receiving tray: keep the equipment running clean. Maintain concentricity and stability. Parallel lifting of the conveyor belt can quickly set the lifting height

Why use an Automatic sand core making machine?

Automatic sand core making machine can greatly improve production efficiency and product quality, and reduce production costs. Compared with traditional hand-made sand cores, automatic sand core machines have the following advantages:

High degree of automation: The automatic sand core making machine adopts the PLC control system, through the automatic control of the program, the fully automated production process can be realized, thereby reducing manual operations and improving production efficiency.

High production efficiency: The production speed of the automatic Automatic sand core making machine is fast, and it can complete the production of multiple sand cores at one time, which greatly improves the production efficiency. According to the actual production needs, the automatic sand core machine can also be mass-produced, which is more in line with the requirements of modern production.

High product quality: The automatic sand core making machine adopts advanced technology and equipment, which can ensure the accuracy and consistency of the sand core, thereby improving product quality. The automatic sand core machine can also make sand cores with complex shapes and internal structures to meet the needs of different customers.

Low cost: The automatic sand core making machine not only improves production efficiency and product quality, but also reduces production costs. Compared with making sand cores by hand, automatic Automatic sand core making machine can reduce labor input, shorten production cycles, and reduce labor costs. At the same time, the automatic sand core machine can also reduce the waste rate of sand cores and reduce material costs