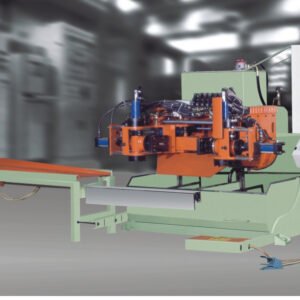

PN2b650-70 gravity die casting machines is a professional casting equipment, suitable for the manufacture of aluminum alloy parts. The equipment adopts advanced hydraulic system and PLC control unit (Mitsubishi), which can realize high-speed and stable casting process, and improve the manufacturing precision and production efficiency of parts.

PN2b650-70 gravity casting machines for aluminium has multiple casting functions, including tilting casting, fixed tilting casting and fixed horizontal casting. These functions allow the machine to be flexibly adjusted according to different production needs, thus achieving efficient casting. At the same time, the equipment also has functions such as adjustable cooling mold time and solid time, so as to better meet different casting needs.

The casting capacity of PN2b650-70 is also very powerful. The hydraulic master cylinder system can control three casting machines. The throwing speed and angle can be adjusted. The size angle can reach 0-85°. The maximum weight can reach 300kg. These parameters can ensure that the equipment can cope with the casting needs of various aluminum alloy parts.

technical parameters

- Control mode: PLC control unit (Mitsubishi) is used for control, which ensures a stable and reliable control system.

- Operation mode: The hydraulic transmission and water cooling system are used to operate, which can ensure the efficient and stable operation of the machine.

- Throwing function: It has the functions of tilting casting, fixed tilting casting and fixed horizontal casting. The casting speed and angle are adjustable, and the size angle is 0-85°, which can meet the needs of different castings.

- Adjustable mold cooling time: According to specific production needs, the mold cooling time can be adjusted to improve production efficiency.

- The size of the fixed mold base: 700mm300mm70mm, can adapt to the manufacture of molds of different sizes.

- The maximum weight of the mold: 300kg, capable of carrying heavier molds.

- Power: 7.5KW, with relatively large power, able to meet high-intensity production requirements.

- Maximum engagement distance: 400mm, which can meet the requirements of castings of different sizes.

- Die fixed plate spacing: 630mm, with a larger fixed plate spacing, suitable for different sizes of mold manufacturing.

- Clamping pressure: 4200kg, with a relatively large clamping pressure, which can meet the requirements of high-quality castings.

- Oil tank capacity: 250L, working oil pressure: 40-50kg/cm2, hydraulic pump power 7.5KW, which can meet the needs of long-term stable work of the machine.

- Adjustable solid time: It can be adjusted according to specific production needs to improve production efficiency.

- Casting time can be displayed: it is convenient for production management personnel to manage production progress.

- If the mold temperature exceeds the limit, the mold will not be measured: effectively guarantee the safety of the mold.

- Net weight of the machine: 3200kg, with a large net weight of the machine to ensure the stable operation of the machine.

- Machine size: 2764mm1720mm1677mm (use space), small space occupation, easy to install and use.

working principle

The gravity die casting machine injects the molten aluminum alloy into the mold through the force of gravity and the inclination of the mold to form the required aluminum parts. First, prepare the required mold, the mold is normally the upper mold part and the lower mold part, the cavity formed between the two is used to hold the molten metal material.

After the preheating of the mold is completed, the inclination is adjusted through a mechanical device or a hydraulic system. When the mold is tilted, the discharge door of the furnace is opened to allow the molten aluminum alloy to enter the cavity of the mold by gravity. The molten aluminum material will flow freely into the mold and fill the cavity in the mold.

After being filled and kept in a tilted state for a period of time, the aluminum alloy cools and solidifies. The length of cooling time depends on the size and shape of the part, as well as the type of aluminum alloy used. Return to the horizontal position to remove the mold and the casting can be taken out.

About PINO

PINO is a gravity die casting machine brand with a history of nearly 40 years, headquartered in Xiamen, China. The company is committed to producing high-quality, high-efficiency, multi-functional gravity die-casting machine equipment, providing advanced technology and reliable products for the global foundry industry.

PINO’s casting machine also has a variety of casting functions, including inclined casting, fixed inclined casting and fixed horizontal casting, etc. These functions can be flexibly adjusted according to production needs, so as to achieve more efficient casting. You can send us your die-casting product drawings, we will recommend the suitable machine for you, and we can also customize the design according to your requirements.