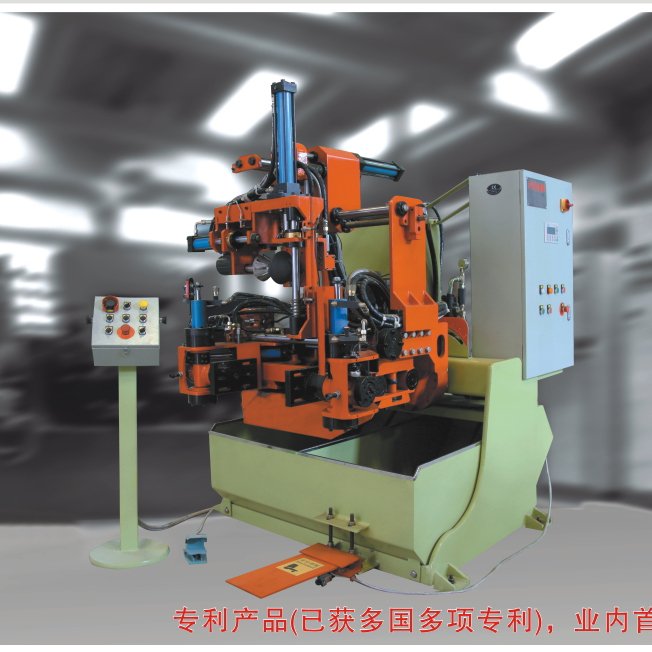

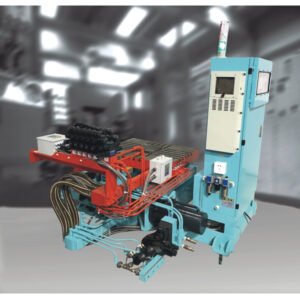

GDC (Gravity Die Casting) die casting machines use the gravity die casting process to produce metal parts for auto parts, industrial equipment and home appliances. PINO Gravity Casting Machine originated from Taiwan. It established a factory in Xiamen in 1988, citing Taiwanese technology and talents. It has a history of decades. Our equipment is constantly innovating and grinding, and the latest generation of GDC die-casting machines has stable performance, long service life and very good quality.

Application

Our GDC die casting machines are commonly used to produce a variety of metal parts with the advantages of high dimensional accuracy, good surface finish and the ability to cast complex shapes with tight tolerances.

Automation

The latest generation of PINO GDC die-casting machines usually has an advanced control system. We use Siemens or Mitsubishi PLC control system, which can monitor and adjust various parameters such as temperature, pouring speed and pressure. The complete system ensures consistent casting quality and process repeatability. At the same time, we are equipped with safety pedals to ensure the safety of operators.

Technical parameter: ( ZD )

- Controlled by PLC control unit

- Running: Hydraulic transmission

- Automatic side pouring

- Pouring package can be cleaned automatically, and its size&initiative angle can be regulated.

- Product weight: 0.5kg- 10kg (two kinds of pouring package)

- Pouring speed& angle can be regulated.

- Pouring methods: automatic& manual

- One cycle time: 20-30 seconds

- Automatic mechanical arm also applies for gravity die casting machines model PN2B360& PN2B03B

- Machine dimension: 1 550mm* 1900* 2050mm

feature

- automatic cleaning of pouring package

- intial state of pouring package(adjustable angle)

- safety footboard (protection device)