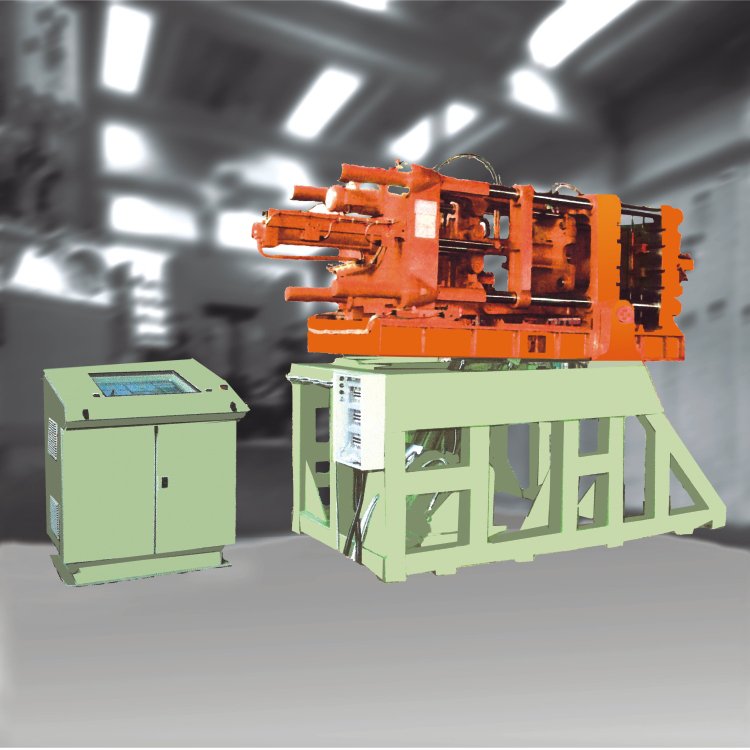

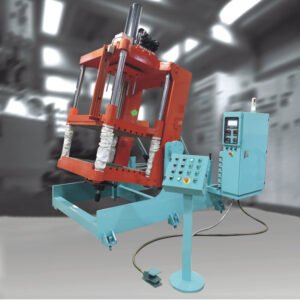

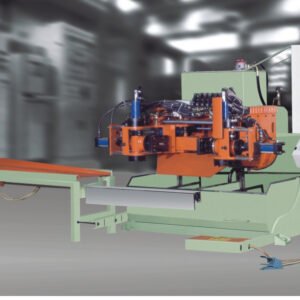

PN2B650-TA is specially designed for the production of auto parts by gravity casting process. Made with a solid frame, robust clamping system and reliable metal pouring mechanism. PN2B650-TA has advanced automation and control system. The PLC control system can precisely control various parameters such as pouring speed, mold temperature and cycle time to ensure repeatability and quality consistency.

PINO’s machines are all equipped with safety features that protect operators and prevent accidents. Includes emergency stop button, safety interlocks and guards.

Many auto parts can use the gravity die-casting process, because the gravity die-casting parts have the characteristics of high density, high precision, complex shape, excellent surface quality, good strength and heat resistance, and lightweight design. According to the size, complexity and material of different auto parts, we will recommend suitable gravity die casting machines for you.

Parameter characteristics

PN2B650-TA is a high-precision and high-efficiency casting equipment, which is widely used in auto parts, mechanical equipment, mold manufacturing and other fields. The following are the detailed technical parameters of the device:

PLC control unit control

PN2B650-TA adopts PLC control system, which is easy to operate and can quickly realize the control and adjustment of the casting process.

Operation

Hydraulic transmission: The equipment adopts hydraulic transmission system, which can provide more stable power support and ensure casting precision and production efficiency.

Clamping force: 100t

The maximum clamping force of PN2B650-TA reaches 100 tons, which can ensure the precision and quality of castings.

Die-cutting board size: 800*800mm

The die-cutting board size of this equipment is 800*800mm, which is suitable for manufacturing castings of various specifications.

Tie rod spacing: 589469mm

PN2B650-TA has a tie rod spacing of 589469mm, which can be adapted to castings of different sizes.

Mold height distance: 250-469mm

PN2B650-TA has a mold height distance range of 250-469mm, which is suitable for various casting requirements.

Mold stroke: 320mm

The mold stroke of PN2B650-TA is 320mm, which can meet various casting needs.

Tie rod diameter: φ75mm

PN2B650-TA’s tie rod diameter is φ75mm, which has sufficient bearing capacity and stability.

Ejection force: 8.5t

The equipment has an ejection force of 8.5 tons, which can easily eject castings.

Ejection stroke: 0-1 20mm

The range of PN2B650-TA’s ejection stroke is 0-120mm, which can be adjusted according to different requirements of castings.

Motor power: 18.75kw

PN2B650-TA uses a 18.75kw motor to provide strong power support.

Machine weight: 7t

The overall weight of PN2B650-TA is 7 tons, which has good stability and reliability.

Machine size: 2500* 1500* 2000mm

The size of the equipment is 2500* 1500* 2000mm, which is suitable for different sizes of plant layout and installation requirements.

In short, the PN2B650-TA gravity casting machine has a high level of automation and intelligence, which can realize efficient and stable casting production and improve the production efficiency of enterprises

advantage

- Consistent and homogeneous parts are produced, and the nature of gravity allows for a more even distribution of material and fewer defects in the product.

- Produce parts of various sizes and shapes. The fine geometric structures and internal cavities in the mold can be accurately filled and reproduced, suitable for the manufacture of automotive parts with complex geometries, such as engine blocks, cylinder heads and transmission housings. They can also be used to produce smaller parts such as brackets, fittings and connectors.

- High production efficiency: Gravity die casting is an efficient casting process that allows for fast cycle times and mass production. The thermal conductivity and rapid injection capability of the mold can improve production efficiency and are suitable for mass production.

- Excellent surface quality: Gravity die casting can produce a smooth, flat surface with good appearance and surface quality. This is very important for automotive parts that require a fine look or require subsequent surface treatments.