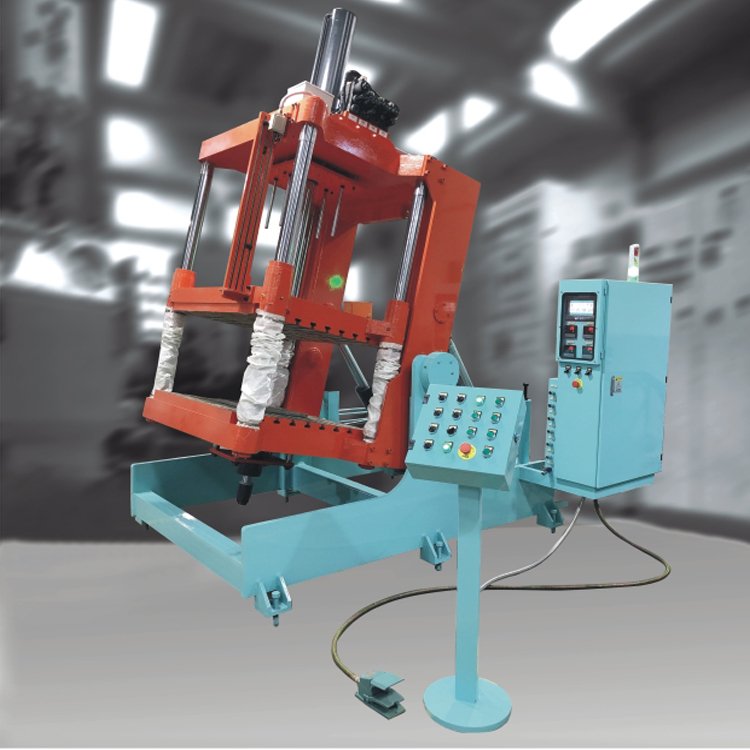

Product introduction: PN2B650-ZL gravity die casting machine for sale

PN2B650-ZL gravity die casting machine is an efficient and intelligent casting equipment with hydraulic transmission and water cooling system, with the following technical parameters:

Controlled by PLC control unit

PN2B650-ZL gravity die casting machine realizes fully automatic control through PLC control unit, which can effectively reduce manual intervention and improve production efficiency and stability. The PLC control unit can automatically control the casting speed and time of the casting according to the demand, realizing the intelligent casting process.

Operation: hydraulic transmission and water cooling system

PN2B650-ZL gravity die casting machine adopts hydraulic transmission and water cooling system, which makes the machine work more stable and reliable. The hydraulic master cylinder system can control three casting machines, and can realize functions such as tilting casting, fixed tilting casting and horizontal casting to meet different casting needs.

Throwing function: tilting throwing, fixed tilting throwing, horizontal throwing

The throwing function of PN2B650-ZL gravity die casting machine can be adjusted according to casting requirements. There are three throwing methods: tilting throwing, fixed tilting throwing, and horizontal throwing, which can meet the needs of different castings and make the casting process more efficient and accurate.

Casting speed and time are adjustable, size angle: 0-85 degrees

The casting speed and time of PN2B650-ZL gravity casting machine can be automatically controlled according to the demand, and the angle range of casting size is 0-85 degrees. The adjustability of casting speed and time enables the machine to adapt to the production needs of different castings, effectively improving the quality and efficiency of casting.

Casting pick-up angle and mold cooling time are adjustable

After casting, removing the casting is a very important step. PN2B650-ZL Gravity Casting Machine provides two selections of casting pick-up angles: horizontal 0 degrees and inclined 85 degrees. At the same time, the mold cooling time can also be adjusted, and the zone cooling with 6 tuyere can be marked from No. 1 to No. 6. The flexibility and adjustability of these functions guarantee high efficiency and high quality of the casting process.

Large size mold and high load-bearing workbench

The size of the movable mold base of the machine is 1000900140mm, the size of the fixed mold base is 1000900180mm, and the size of the top plate of the fixed mold is 45032020mm. The rotating load of the workbench is up to 4000kg, the power is 11KW, the maximum meshing distance is 700mm, and the maximum distance between the mold fixing plates is 1200mm. These large-scale molds and high-load-bearing tables provide the necessary support and assurance for large-scale castings and can meet various industrial needs.

High pressure clamping and adjustment functions

PN2B650-ZL gravity die casting machine adopts high-pressure mold clamping, and the clamping pressure is as high as 6300kg to ensure the molding effect of castings. At the same time, it is also equipped with an adjustment function, the casting speed and time can be adjusted, and the size and angle range is wide, providing a richer working space for the foundry.

Intelligent control and display function

PN2B650-ZL gravity casting machine is controlled by PLC control unit, equipped with intelligent control and display functions, through which users can directly operate the machine and monitor the casting process. In addition, it is also able to display the casting time, which is convenient for users to track the work progress and effect.

Stability and Durability

PN2B650-ZL gravity casting equipment adopts hydraulic transmission and water cooling system, which can provide a more stable and reliable working environment. The power of the hydraulic pump reaches 11KW, the capacity of the fuel tank is 250L, the working oil pressure is 40-50kg/cm2, and the solid time is adjustable. The net weight of the whole machine is about 7000kg, and the size of the machine is 3241mm*2495mm*2266mm (working space). It also has protective devices to ensure the safety and durability of the machine.

PN2B650-ZL gravity die casting machine, with its high automation and flexibility, can be widely used in the casting of aluminum, magnesium alloy and copper, such as automobile, aircraft, ship and other parts.

Maximum engagement distance: 700mm

The PN2B650-ZL gravity casting machine is equipped with a maximum engagement distance of 700mm, which enables it to accommodate larger size castings at the same time. This means customers can more efficiently produce castings in a variety of sizes and shapes, increasing productivity and throughput. Whether it is large or small mechanical parts, the machine is capable of efficient casting.

Maximum distance between mold fixing plates: 1200mm

The PN2B650-ZL Gravity Casting Machine has a maximum pitch of 1200mm between the mold fixing plates, which is another key feature to ensure that the machine is suitable for large castings. Customers can take advantage of this feature to produce larger, heavier and more complex castings, increasing the machine’s versatility and production capacity.

Clamping pressure: 6300kg

Clamping pressure is one of the important casting parameters of PN2B650-ZL gravity casting machine. Equipped with a clamping pressure of 6300kg, the machine can produce castings with higher density, fewer defects and better appearance while maintaining high-quality castings. This can greatly improve the production efficiency of customers, while saving materials and costs.

Oil tank capacity: 250L, working oil pressure: 40 -50kg/cm2, hydraulic pump power 11KW

The PN2B650-ZL gravity casting machine adopts a high-efficiency hydraulic system, which can operate normally with a 250L oil tank capacity and a working oil pressure of 40-50kg/cm2. The power of the hydraulic pump is 11KW, which provides strong power support. These features can ensure that the machine maintains high efficiency and stability in long-term continuous work, thereby achieving higher production efficiency and lower costs.

The solid time is adjustable, and the casting time can be displayed

The solid time of the PN2B650-ZL Gravity Casting Machine is adjustable, enabling customers to make adjustments as needed while maintaining casting quality. In addition, the machine can display the casting time, enabling customers to better control the production process and detect and solve potential problems in time. These features make the machine more intelligent and easy to operate.

Maximum engagement distance: 700mm

The PN2B650-ZL gravity die casting machine is equipped with a maximum engagement distance of 700mm, which enables it to accommodate larger size castings at the same time. This means customers can more efficiently produce castings in a variety of sizes and shapes, increasing productivity and throughput. Whether it is large or small mechanical parts, the machine is capable of efficient casting.

Maximum distance between mold fixing plates: 1200mm

The PN2B650-ZL Gravity Casting Machine has a maximum pitch of 1200mm between the mold fixing plates, which is another key feature to ensure that the machine is suitable for large castings. Customers can take advantage of this feature to produce larger, heavier and more complex castings, increasing the machine’s versatility and production capacity.

Clamping pressure: 6300kg

Clamping pressure is one of the important casting parameters of PN2B650-ZL gravity casting machine. Equipped with a clamping pressure of 6300kg, the machine can produce castings with higher density, fewer defects and better appearance while maintaining high-quality castings. This can greatly improve the production efficiency of customers, while saving materials and costs.

Oil tank capacity: 250L, working oil pressure: 40 -50kg/cm2, hydraulic pump power 11KW

The PN2B650-ZL gravity casting machine adopts a high-efficiency hydraulic system, which can operate normally with a 250L oil tank capacity and a working oil pressure of 40-50kg/cm2. The power of the hydraulic pump is 11KW, which provides strong power support. These features can ensure that the machine maintains high efficiency and stability in long-term continuous work, thereby achieving higher production efficiency and lower costs.

The solid time is adjustable, and the casting time can be displayed

The solid time of the PN2B650-ZL Gravity die Casting Machine is adjustable, enabling customers to make adjustments as needed while maintaining casting quality. In addition, the machine can display the casting time, enabling customers to better control the production process and detect and solve potential problems in time. These features make the machine more intelligent and easy to operate.

Net weight of the whole machine: about 7000kg, machine size: 3241mm*2495mm*2266mm (working space)

The net weight of the PN2B650-ZL machine is about 7000kg, and the machine size is 3241mm *2495mm *2266mm. It has sufficient working space to meet various casting needs.

At the same time, the machine also has the characteristics of easy installation and movement. The installation of the PN2B650-ZL gravity casting machine does not require complex foundations and fixed facilities, only simple preparations are required, so it can be put into production quickly. In addition, the machine is also equipped with moving wheels, which is convenient for moving and adjusting the position in the factory to suit the needs of the production line.

PN2B650-ZL gravity die casting machine, as an advanced casting equipment, has been widely used in aviation, automobile, military, petroleum, chemical, energy and other industries. Its efficient casting process and precise control system can greatly improve production efficiency and product quality, and help enterprises gain greater advantages in market competition.

The following are PN2B650-ZL mold die-casting products, the structure will be more complicated, suitable for gravity casting.