The brass gravity die casting machine uses Siemens PLC, which is the most stable control system in the world, and the overall process is driven by a hydraulic system, which has been the strong point of the PINO series gravity casting machine, our hydraulic system is stable and will not jam. The biggest feature of gravity die casting machine is that it has Ejection function & core-pulling function (adjustable distance & speed of the ejection & core-pulling; adjustable different phases).

Technical Parameters

- Control system: The casting equipment adopts advanced Siemens PLC control unit for automatic control and monitoring. During the production process, if there is a problem, the operator can quickly diagnose and troubleshoot by touching the text and color pictures displayed on the screen, thus ensuring the reliability and stability of the equipment.

- Casting capacity: PN2B03B-IID copper gravity die casting machine adopts hydraulic transmission technology, which can realize the adjustable casting speed and angle. Wide range of casting speed and angle can be adjusted according to different production requirements. At the same time, the maximum mold diameter of this equipment can reach 500mm, and the maximum casting capacity can reach 200kg, which can meet the needs of different casting processes.

- Casting method: The equipment supports automatic and manual casting methods, which can be selected according to actual production needs. The automatic casting method improves production efficiency and stability, and the manual casting method can better meet some special needs.

- Dip tank: PN2B03B-IID copper gravity die casting machine’s dip tank stirrer adopts blade motor to ensure the uniformity of dipped copper water, thereby ensuring the quality and stability of the product. In addition, the equipment is equipped with an immersion tank solution temperature control system (optional), which can control the temperature of the copper water in the immersion tank, thereby further ensuring the stability and quality of casting.

- Casting method: the equipment supports side casting, front casting and combined casting, which can be flexibly selected according to product requirements.

- Ejection core-pulling: This equipment has the function of ejecting core-pulling, the distance and speed of ejecting core-pulling are adjustable, and the different stages are adjustable. In addition, operators can make adjustments via the device’s touch screen.

- Safety: In order to ensure the safety of the operator, the equipment has a safety foot pedal (operator protection device), which must be stepped on during operation to cast.

- Cooling: PN2B03B-IID copper gravity die casting machine is equipped with 4 cooling water pipes in the dipping tank for water cooling, and the cooling time and frequency can be set individually.

- Dip tank liquid temperature control system (optional): This copper gravity die casting machine can be equipped with dip tank liquid temperature control system, which can effectively control the temperature of the copper liquid in the dip tank during casting, improve the stability and reliability of casting, and at the same time It can also reduce the waste of copper materials and improve production efficiency.

- Total time of one cycle: 20-30 seconds: The total time of a complete casting cycle of this copper gravity die casting machine is 20-30 seconds, which can greatly improve production efficiency, shorten production cycle, and at the same time ensure the quality and stability of castings.

- Water pump power: 3.75KW+0.75KW+0.75KW: The water pump power of the copper gravity die casting machine is 3.75KW+0.75KW+0.75KW, which can provide sufficient cooling water source for the dipping tank and ensure the temperature control during the casting process and stability.

- Dimensions (length, width and height) (150024001800) MM: The overall dimension of this copper gravity die-casting machine is 150024001800 mm, and the floor space is relatively small, which can be flexibly arranged and installed in the factory, and it is also convenient for daily maintenance and maintenance.

- PINO has CE certification: This copper gravity die casting machine has passed CE certification and complies with European quality and safety standards. It can be sold and used in the European market and other markets that recognize CE standards. Customers can buy and use with confidence.

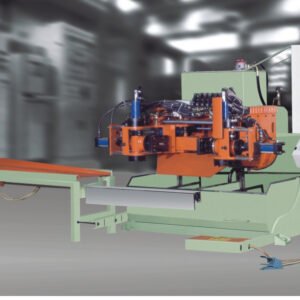

2 detail drawings of PN2B03B-IID

Brass alloys can be formulated according to different requirements, such as other metal alloys such as zinc, to obtain the required mechanical properties, corrosion resistance and other characteristics. Brass alloys are widely used in gravity die casting. Let’s take a look at what medicine chooses brass as gravity die casting material:

- Good fluidity: Brass has good fluidity. During the casting process, brass can smoothly fill the cavity in the mold, and can fill small and complex geometric shapes, suitable for gravity casting.

- Excellent mechanical properties: Brass has good mechanical properties, including high strength, hardness and wear resistance. It also has good corrosion resistance and is suitable for use under various environmental conditions.

- Good thermal conductivity: Brass has high thermal conductivity, which can transfer and disperse heat quickly. In this way, products with the required heat dissipation performance, such as radiators and heat exchangers, can be gravity cast from brass.

- Good machinability: Brass is easy to process and form, and can be drilled, milled, turned and threaded. This allows subsequent machining and finishing of gravity cast brass products.

- Corrosion resistance and aesthetics: Brass has good corrosion resistance and good stability to many chemicals and environments. In addition, brass also has a golden-yellow appearance, which can bring a unique aesthetic effect to the product.

What industry is brass gravity die casting mainly used for?

Brass gravity die casting is mainly used to manufacture various mechanical parts, electrical devices, pipes and devices, etc. In the field of machinery manufacturing, brass gravity casting parts are usually used in automobiles, motorcycles, mechanical equipment and other industries, such as engine parts, clutch housings, gearbox parts, valve seats, shock absorber seats, etc. In terms of electrical devices, brass gravity die-cast parts are often used to manufacture sockets, switches, plugs, sockets, coils, etc. In addition, brass gravity cast parts are also widely used in construction, furniture, bathroom and other industries, such as door handles, faucets, drainage systems, etc.