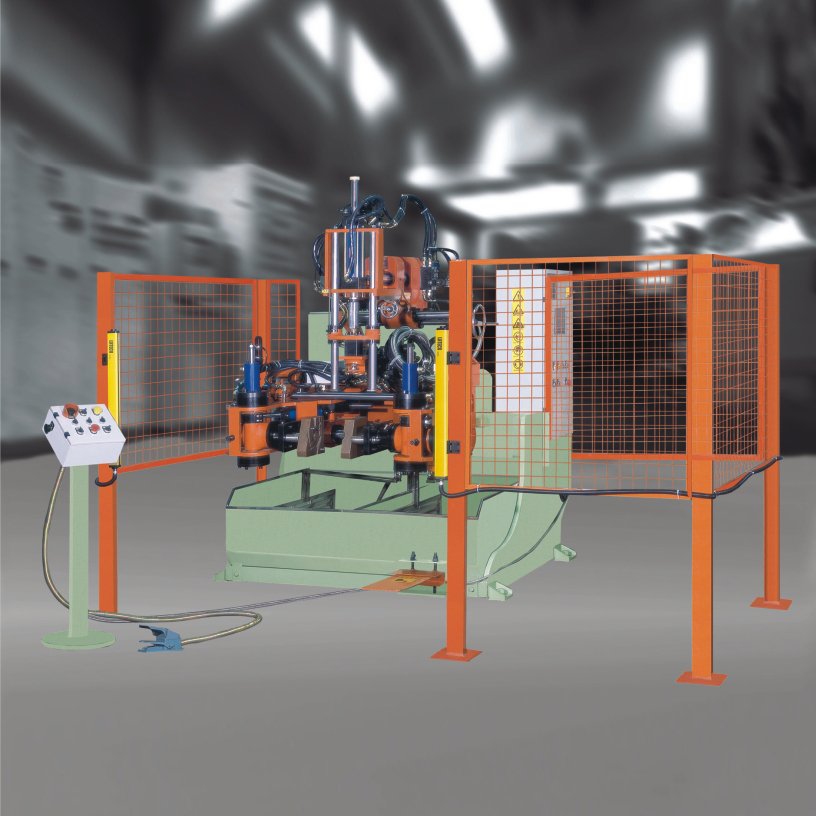

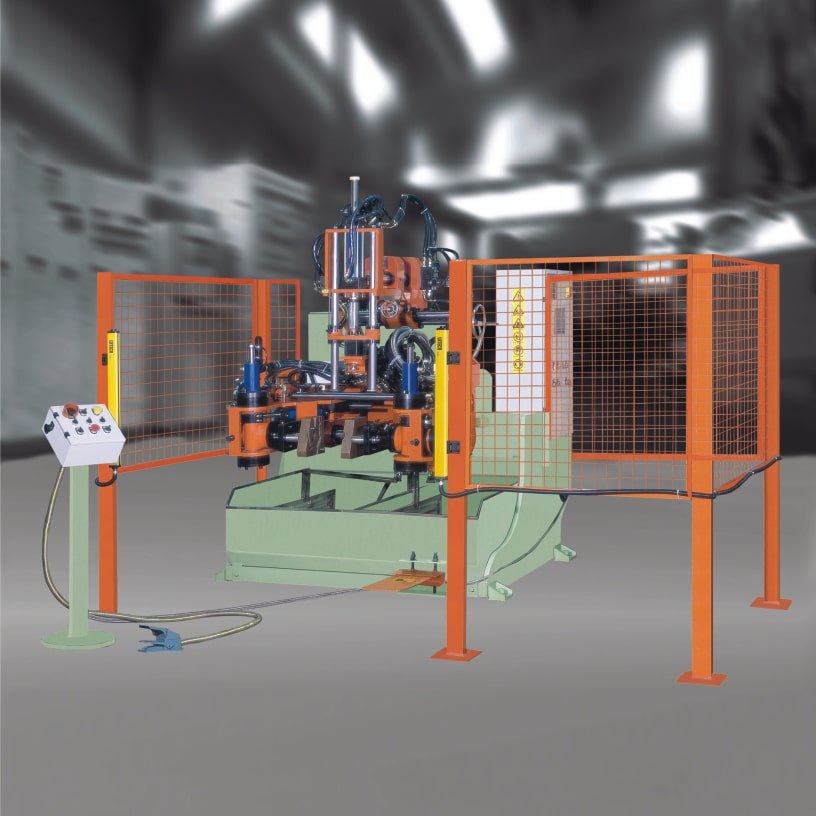

PN2B03B-ZX automatic tilting gravity casting machine is an efficient and precise casting equipment, which adopts advanced electrical control and hydraulic system to complete the casting process under the action of gravity. The machine can core-pulling or as a third direction of mold is suitable for the structure of complex casting products. It is widely used in the production of various metal alloy parts, such as automobiles, aviation, engineering machinery, electronics and other fields.

Our PN2B03B-ZX automatic tilting gravity casting machine adopts high-quality materials and advanced manufacturing technology, which is compact in structure, stable and reliable, and has the advantages of high casting efficiency, good casting quality and low energy consumption. Through automatic control, the automation and digitization of the casting process can be realized, which greatly improves the casting efficiency and production efficiency.

PN2B03B-ZX automatic tilting gravity casting machine also has reliable safety protection measures, such as automatic identification of mold abnormalities, automatic adjustment of tilt angle and other functions, to ensure the safety and stability of the casting process.

PINO is a brand with 40 years of manufacturing experience. We are a factory specializing in the production of gravity casting machines. We have an experienced and skilled team that can provide customers with customized casting solutions according to their needs and requirements. plan. Adhering to the concept of “quality first, customer first”, we continue to improve and innovate, and are committed to providing customers with high-quality, high-efficiency gravity casting machines.

PN2B03B-ZX automatic tilting gravity casting machine Technical Parameters:

- Controlled by a PLC control unit.

- Have automatic detection, if occurs problems, it will show the problem by words and color pictures on the touch screenwhich help users to find and solve the problems very easily and quickly.

- Running: Hydraulic Transmission.

- The stir method of dipping tank: By vane electric machinery.

- Casting Function: Side pouring, frontal pouring, Combined pouring.

- Casting speed & angle are adjustable. Size angle: 0-90, frontal angle 0-110, mold steeping angle 0-90

- Max. Mold diameter: 520mm

- Max. Casting Volume: 150kg

- The time & frequency of cooling can be set up individually.

- Casting method: Automatic & Manual.

- Ejection function (optional)

- Having Safety footboard

- Security fence and infrared grating

- Three-color warning light

- Top core-pulling

- One cycle total time: 20-30 seconds.

- Pump power: 3.75KW+0.75KW+0.75KW

- dimensions (L*W*H)(2700*1500*2100)MM

- Have CE certification

Advantages of Automatic Tilting Gravity Casting Machine

The automatic tilting gravity casting machine has the feature of tilting. Compared with the fixed casting machine, it has the following advantages:

1. The casting process is more stable

During the casting process, the tiltable feature of the casting machine can make the molten metal evenly distributed in the casting cavity, thereby reducing defects such as air bubbles and oxide scales during the casting process, and improving the quality and mechanical properties of the casting.

2. Higher casting precision

The automatic tilting gravity casting machine can achieve higher precision casting by precisely controlling the tilting angle and time, and the dimensional accuracy and surface quality of castings are better.

3. Wider scope of application

The automatic tilting gravity casting machine can be applied to various casting materials and casting types, and the casting range is wider.

4. Higher casting efficiency

The tiltable casting machine can realize the digitization and automation of the casting process through automatic control, improve casting efficiency, and reduce manual intervention and human error.

5. Lower energy consumption

Compared with traditional stationary casting machines, tilting casting machines consume less energy during the casting process, because the molten metal can make better use of gravity without requiring additional pressure and energy.

To sum up, the automatic inclined gravity die casting machine has higher casting precision, wider application range, higher casting efficiency and lower energy consumption, which can meet various casting needs of customers.

What material is the PN2B03B-ZX automatic tilting gravity casting machine used for casting?

- Aluminum alloy: The automatic tilting gravity casting machine can cast various aluminum alloys, such as ADC12, A356, A380, etc.

- Magnesium alloy: The automatic tilting gravity casting machine can also cast magnesium alloy, such as AZ91D, AM60B, etc

- Copper Alloys: The automatic tilting gravity casting machine can cast various copper alloys, such as brass, bronze, etc

- Steel, iron and other metals: Although the automatic tilting gravity casting machine is mainly suitable for casting non-ferrous materials, it can also be used for casting steel, iron and other metals in some special cases.

We recommend PN2B03B-ZX gravity die casting machine to customers who cast copper and copper alloys, and we usually recommend PN2B650 aluminum gravity casting machine for aluminum alloys.

Different metal materials require different casting process parameters and mold designs, so strict casting process and mold design evaluation and optimization are required before casting.