PINO’s tilting gravity die-casting machine adopts PLC control system, which has a high degree of automation. The main working principle is that by injecting molten aluminum into the mould, the machine will automatically work according to the set inclination angle, and form under the action of gravity. The tiltable gravity die-casting machine can complete the tilted pouring of the mold shell, especially suitable for the forced casting of various castings such as intake manifolds. The pouring speed and angle of our machine can be adjusted. The angle range of side pouring is 0-90 degrees, and the angle of front pouring is 0-110 degrees. It can be started and stopped at any time within this range. Some ejection and core-pulling designs, we can also customize the design according to your requirements.

Compared with the tiltable gravity casting machine and the fixed gravity casting machine, the tiltable gravity casting machine can reasonably improve the inner quality of the castings, and is suitable for various non-ferrous metal castings, such as faucets, faucets, etc. Tilting gravity casting machines are preferred over stationary gravity casting machines for the following reasons:

- Improve casting quality: By altering the tilt angle and speed of the tiltable gravity casting machine, you can better regulate the flow and solidification of the metal liquid, resulting in more uniform and precise castings. This tight control aids in the reduction of flaws as well as the improvement of casting strength and mechanical qualities.

- Improve production efficiency: The tiltable gravity casting machine uses an automated control system, which simplifies operation and makes the manufacturing process more stable, reducing operator technical requirements and increasing production efficiency. Simultaneously, time and money are saved due to improved casting quality, lower reject rates, and less need for further processing.

- Extended application range: The tiltable gravity casting machine is suitable for a variety of metal materials, including aluminum, copper, magnesium and other alloys. This makes it more widely used in different industries, such as automotive manufacturing, aerospace, electronics, etc.

- Energy saving: Compared with traditional stationary gravity casting machines, tiltable gravity casting machines require lower temperature of liquid metal during casting, thus saving energy consumption.

- Reduced Mold Costs: Since the tiltable gravity caster provides better control over the flow of metal, mold filling pressure is reduced, allowing for simpler and less expensive molds.

- Environmental advantages: Compared with some other casting methods, such as die casting, the tiltable gravity casting machine produces less waste and emissions, which is conducive to environmental protection.

To sum up, the tiltable gravity casting machine is more popular in industrial production due to its excellent casting quality, high efficiency, wide application range, energy saving and environmental protection.

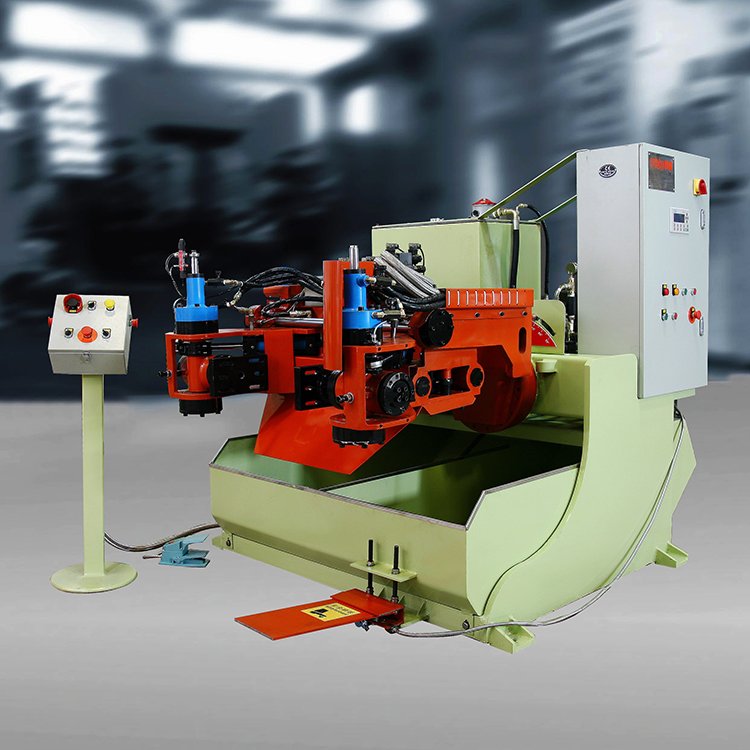

PN2B03B Technical Parameters:

- Controlled by a PLC control unit.

- Have automatic detection, if occurs problems, it will show the problem by words and color pictures which help users to find and solve the problems very easily and quickly.

- Running: Hydraulic Transmission.

- The stir method of dipping tank: By vane electric machinery.

- 5Casting Function: Side pouring, frontal pouring, Combined pouring

- Casting speed & angle are adjustable. Size angle: 0-90 frontal angle 0-110, mold steeping angle 0-90

- Max. Mold diameter: 500mm

- Max casting volume:150kg

- The time & frequency of cooling can be set up individually.

- Casting method: Automatic & Manual.

- Ejection function (optional)

- Having Safety footboard

- One cycle total time: 20-30 seconds.

- Pump power: 3.75KW+0.75KW+0.75KW

- Dimensions (L*W*H) (1500*2400*1800)

- Have CE certification

PN2B03B Tilting gravity die casting machine die plate:

PN2B03B Tilting gravity die casting machine Die casting products:

About PINO

The side pouring angle of the inclined gravity die casting machine ranges from 0 to 90 degrees. Within this range, this position can be adjusted at any time. We have a convenient adjustment method. Including the adjustment of the forward tilt angle, the positions of the two adjustment ps are different, but it is easy to find. The speed of side pouring and front pouring can also be adjusted according to the casting conditions.

PN2B03B Tilting Gravity Die Casting Machine is mainly used for copper die casting and copper alloy die casting. Copper die-casting gravity die-casting machines have been exported to Turkey, Brazil, Pakistan and other countries since 1999, and are widely used in the water meter and faucet industry. Of course, PINO also has PN2B650 series aluminum gravity die-casting machines, sand core machines, etc. Welcome to consult.

Why choose PINO

- With over 30 years of equipment production experience, we are a competent gravity casting machine manufacturer in China.

The quality of the equipment is critical. Our equipment has been in operation for many years, and all difficulties have been resolved. - We have extensive expertise in gravity casting and can provide appropriate machines and solutions to you.

- We export to the worldwide market, and the control system may be configured in any language.

- We can immediately change the mold plate of imr equipment without modifying it.

Our equipment is more power-efficient and efficient after performance optimization, and the hydraulic system is stable and will not get stuck.