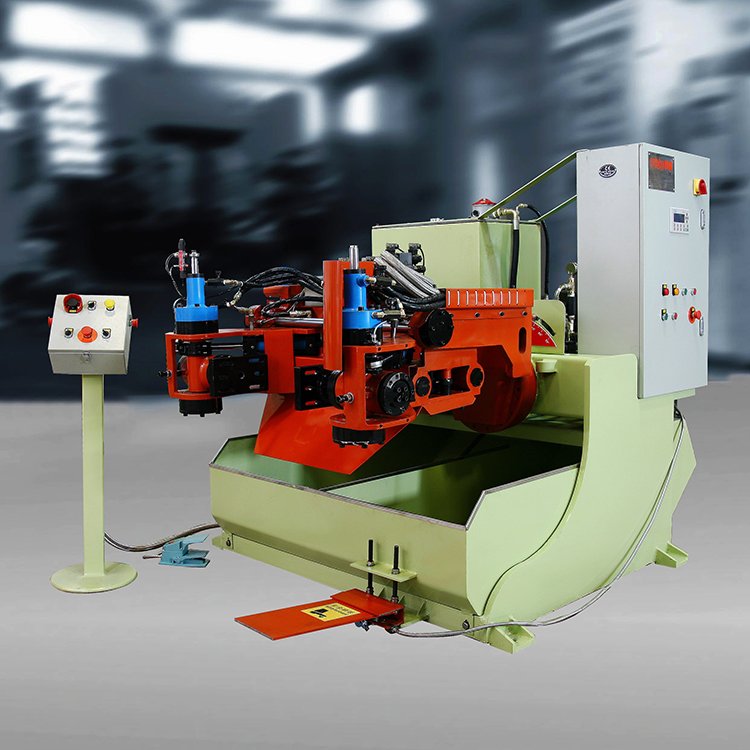

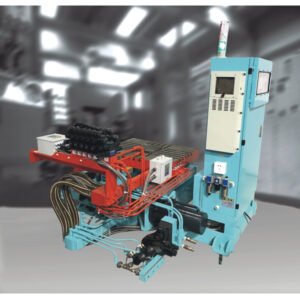

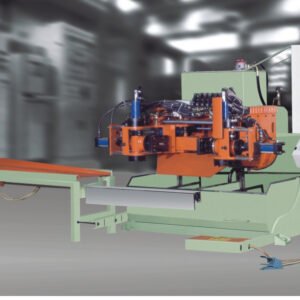

PN2B360 Automatic Gravity Die Casting Machine is a device specially designed for gravity casting of copper and copper alloys. The machine is controlled by a PLC control unit and has an automatic detection function, which can find and solve problems conveniently and quickly, and display the problems in text and color pictures, making the user operation more simple and convenient. The operation mode is hydraulic transmission, and the stability and high efficiency are guaranteed. The mixing method of the dipping tank is a blade motor, which can fully stir the copper liquid and ensure the uniformity of the casting.

technical parameters:

Control unit: controlled by PLC control unit to ensure efficient and stable operation of the equipment and improve production efficiency.

Automatic detection function: The equipment has an automatic detection function. Once a problem occurs, it will be displayed in text and color pictures to help users quickly find and solve problems and improve production efficiency.

Operation mode: The equipment adopts hydraulic transmission, which can realize high-speed and high-precision casting process.

Stirring method: The dipping tank is stirred by a blade motor, which has a good stirring effect and ensures uniform pouring.

Pouring function: the equipment supports side pouring, front pouring and combined pouring, with high flexibility and suitable for different casting process requirements.

Adjustable throwing speed and angle: The equipment supports the adjustment of throwing speed and angle, which can be adjusted according to needs to ensure the quality and accuracy of castings.

Maximum mold diameter and weight: The maximum mold diameter of the equipment is 360mm, and the maximum mold weight is 100kgs, which is suitable for casting needs of various molds.

Cooling time and frequency: The equipment supports separate setting of cooling time and frequency, which can be adjusted according to different casting needs.

Pouring method: The equipment supports automatic and manual pouring methods, and the operation is simple and flexible, which is suitable for different casting process requirements.

Pop-up function: The equipment can be equipped with a pop-up function to facilitate the removal and cleaning of castings.

Safety: The equipment is equipped with a safety foot pedal to ensure the safety of the operator.

Cooling pipe and liquid temperature control system: The equipment is equipped with 3 cooling pipes for water cooling in the dipping tank. The dipping tank liquid temperature control system is optional to ensure the stability and consistency of casting.

Total cycle time: The total cycle time of the equipment is 20-30 seconds, and the production efficiency is high.

Power and size: The power of the equipment is 3.75KW+0.75KW+0.75KW, the machine size is 2130mm*1450*1720mm, small and exquisite, easy to move and install.

Certification: The equipment has passed CE certification, and the quality is guaranteed.

Advantages of PN2B360 Automatic Gravity Die Casting Machine

Automatic Gravity die casting machines also feature an eject function (optional) for easier removal of castings. At the same time, the machine is equipped with a safety foot pedal to ensure the safety of the operation. In terms of cooling, the machine is equipped with 3 cooling pipes for water cooling in the dipping tank. For users who require higher requirements, an optional dipping tank liquid temperature control system can be used to control the temperature of the aluminum liquid more accurately and improve the quality and stability of the product.

In terms of operation, the Automatic Gravity die casting machines adopts hydraulic transmission, which can ensure stability and high efficiency. In terms of pouring, it has various pouring methods such as side pouring, front pouring, and combined pouring to meet the production needs of products of different shapes and sizes. Throwing speed and angle can also be adjusted as needed. The cooling time and frequency can be set individually to meet different process requirements.

The maximum mold diameter is 360mm, and the maximum mold weight is 100kgs, which can adapt to the production of molds of different sizes. The power of the whole machine is 3.75KW+0.75KW+0.75KW, and the size of the machine is 2130mm*1450*1720mm, which is relatively compact. At the same time, the product has also passed CE certification and meets the quality requirements of the European market.

In general, PN2B360 automatic gravity die casting machine has multiple functions and technical advantages, can adapt to different production needs, and has high stability and safety, which is worthy of the choice and trust of the majority of users.