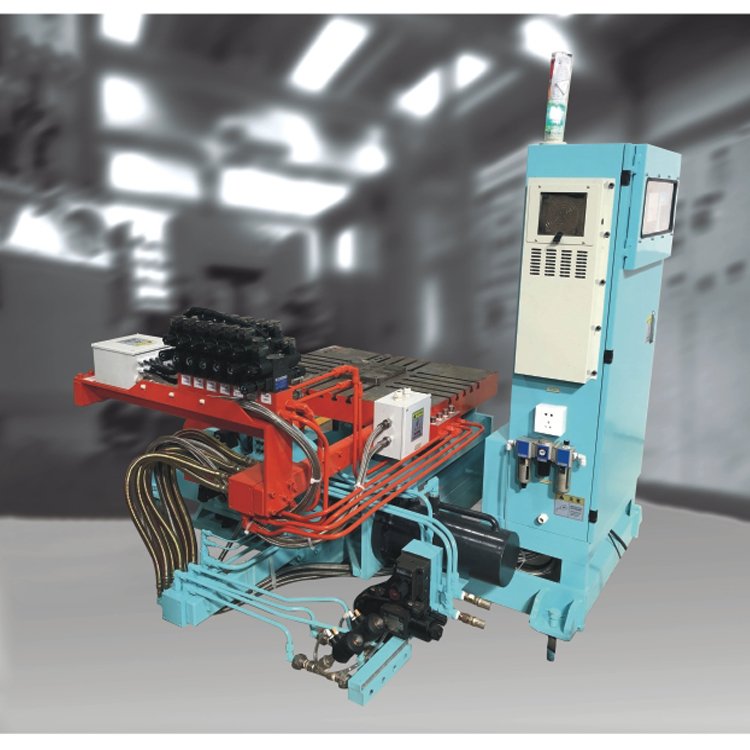

PN2b650-ZS is a high-performance Gravity die Casting Machine equipment specially made by PINO for the gravity die casting industry. Its design and manufacture are in compliance with international standards. It is a powerful and easy-to-operate equipment. The equipment adopts PLC control system, which can realize high-precision control and is easy to operate. At the same time, the PN2b650-ZS equipment is driven by a hydraulic system, which can ensure the stability and safety of the equipment.

PN2b650-ZS Technical parameter:

- Device: PLC control

- Operation:Hydraulic system transmission, water cooling test cooling system(1 hydraulic main pump system can control 3 pouring machines).

- Pouring function: inclined pouring, inclined positioning pouring,horizontal pouring.

- The tubing interface is divided into six separate control channels, which

can be used to connect the closing and opening cylinders, and the operation of the opening and closing mode is controlled by time. The equipment is not equipped with the opening and closing mode cylinders.

(The customer has designed the opening and closing cylinder on the die)

- Casting rotation speed and time can be adjusted: inclined casting angle 0-90 degrees.

- Mould cooling time can be adjusted. It can be cooled in zones with two air outlets (numbered 1-2).

- Workbench size: 900* 700* 100mm.

- Rotary rack cylinder 150*250mm

- Extrusion cylinder 100 * 50mm adjustable 40mm

- Ejector: 250*250*20

- Maximum die weight: 400 kgs.

- Rotary bearing capacity of worktable 1000 kgs

- Power: 7.5KW.

- Fuel tank volume: 250L.

- Working oil pressure: 30-40 kg/cm2.

- Curing time: adjustable.

- The casting process time can be displayed.

- Temperature of the die can be displayed and the heating of the die can be controlled by time.

- There is a mould water cooling pipeline system with one inlet and one outlet for the upper and lower dies. (The water source for the equipment and the connecting pipe for the mould are provided by the customer.)

- There is a heating system for the mould. (The connecting line and heating rod of the mould are provided by the customer) There are two heating modes, which can be divided into two sections (total power 10000 W).

- Net weight of equipment: about 1500kg

- Machine specifications: 1997*1543*1765

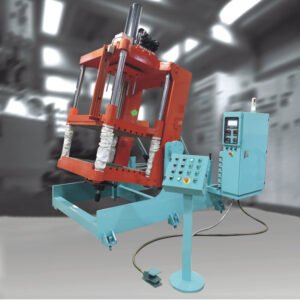

Advantages of PN2b650-ZS Gravity die Casting Machine

PN2b650-ZS Gravity die Casting Machine is an equipment with many advantages and features, it adopts advanced accessories such as advanced PLC control system and water cooling test cooling system, so it has high performance and high stability. The advantages of PN2b650-ZS gravity die casting machine are:

- In order to ensure production efficiency and product quality, PN2b650-ZS equipment is equipped with a water-cooled test cooling system, which can effectively reduce the temperature of the equipment, reduce the failure rate of the equipment, and improve production efficiency and product quality. In addition, the equipment can control three pouring machines through a single hydraulic main pump system, which can greatly reduce production costs and improve production efficiency.

- PN2b650-ZS equipment has a variety of pouring functions, including inclined pouring, inclined positioning pouring and horizontal pouring. The choice of these pouring methods depends on the needs of the customer, making the production process more flexible and efficient.

- The oil pipe interface of the equipment is divided into six independent control channels, which can be used to connect the closing and opening cylinders. This design can realize the running time control of the opening and closing modes, so that the operation of the equipment is more convenient and efficient. In addition, the equipment is not equipped with mold opening and closing cylinders, but customers can design opening and closing cylinders on the mold to meet different production needs.

- The overall design of PN2b650-ZS equipment has good stability and reliability, which can ensure the long-term operation of the equipment. At the same time, the equipment is equipped with rich safety protection functions, such as overload protection, pressure protection and temperature protection, etc., which can ensure the safe operation of the equipment.

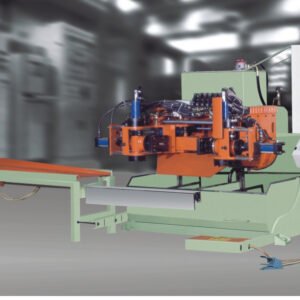

PINO is a professional gravity die casting machine manufacturer

As a professional gravity casting machine brand, PINO has a long history and rich experience, and is committed to providing users with high-quality, high-performance gravity casting machine and high-quality after-sales service. PN2b650-ZS gravity casting machine, as an excellent product of PINO, is well received and trusted by customers for its high performance, high stability, high efficiency, and easy operation.