Rich manufacturing experience

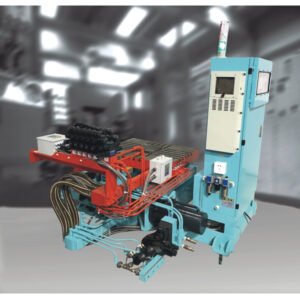

Start customizing your gravity die casting machine

To customize the PINO gravity casting machine, it is necessary to formulate a suitable design plan first, carry out the structural design of the casting machine and the manufacture of parts, and finally carry out the assembly, trial operation and debugging of the casting machine to obtain a high-quality gravity casting machine that meets the needs of customers.

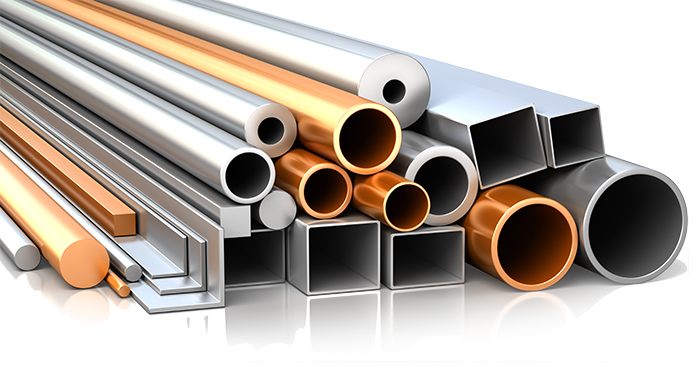

First of all, it is necessary to determine the design and specifications of the parts to be manufactured, including requirements for size, shape, material, weight, surface treatment, etc. If required, detailed drawings or CAD files of the parts are also required.

According to the requirements of the part, select the appropriate gravity casting material, including aluminum alloy, copper alloy, magnesium alloy, etc. Then determine the parameters such as mold design, gating system design, casting temperature, pressure and time.

Assemble the finished casting machine parts to test the feasibility of the casting machine and optimize the process parameters. Carry out trial operation and debugging on the assembled casting machine to ensure that the performance and indicators of the casting machine meet the design requirements.